Post frame construction is having a notable impact on new construction. It’s the preferred type of development for many kinds of commercial buildings. As well increasingly a popular choice for residential buildings. Economical and long-lasting, post frame structures are more than those simple structures that were used as agricultural buildings. Today, post frame is popular for offices, residences, new churches and schools, retail facilities, and firehouses.

While the underlying framing and support methods are different than conventional metal or stick frame structures, the exterior cladding can be the same. Any siding or roofing material used for other types of buildings can be used on most post frame building types. Therefore, brick, wood, stains and paints, stone, or stucco plus shingles and most other roofing materials can be used on post frame buildings.

Post frame is merely a different type of framing system that meets all building codes and will provide a long-lasting and attractive building at lower cost and greater flexibility. Contact Pacemaker Post Frame Buildings for more information.

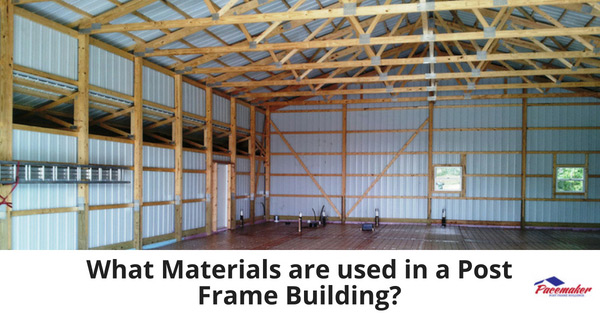

While the materials for the newest post frame buildings vary somewhat, the materials described are typical for this type of framing system.

Materials Used in Post Frame Structures

Pressure Treated Laminated Post

The critical elements of a post frame structure are the treated below grade wood vertical columns that support the weight of the structure. These posts sink into the ground at least four feet. In addition, generally six to ten feet apart from each other. These beams get the highest rating for durability by the American Wood Protection Association (AWPA. They meet all relevant building codes for ground exposure.

The wood posts anchor on concrete piers or metal collars for protection and stability. Post frame buildings, by design, are incredibly durable in storms because of the “designed diaphragm effect”. This refers to the redistribution the wind forces down through the wood columns into the ground below.

The posts may be 4”x4”, 5”x5”, or 8”x8” treated for underground exposure. The post size depends mainly on the size and scope of the structure and the areas loading requirements, respectively.

Treated Bottom Plates

Also, the 2”x10” bottom skirt board are the pressure treated wooden planks connecting the vertical posts around the perimeter at ground level. These can be used as the forms for pouring a concrete slab floor.

Header Plates

These wooden reinforcements typically 2”x8” to 2”x12”are for larger open spans and straddle the vertical posts at the top. They run laterally to provide extra strength and support.

Wall Girts

2”x4” and 2”x6” wall girts provide extra support to the entire structure. These commonly run laterally across the vertical posts at 24”-36” on center intervals.

Trusses

Triangulated wooden structures, factory-made trusses designed for the specific type and size of the post frame building are designed to carry the maximum roof load to the wall posts of the structure. Prefab trusses are lengths of lumber of a special design for specific size and pitch. Additionally, the cost is less and the design is specific than on-site construction. The trusses meet all building code requirements and can span long distances without the support of weight bearing interior walls.

Roof Purlins

Spaced 24” apart, 2”x4” roof purlins are the horizontal members running parallel to the eaves to further reinforce the weight-bearing capability if the roof.

Exterior Materials

The look of your post frame building is up to your imagination. The same claddings and roofing materials for any other building types work for post frame construction.

Contact Pacemaker Post Frame Buildings

For information regarding the design, materials, and construction of an energy-efficient, versatile, and economical post frame building, contact the professionals at Pacemaker Post Frame Buildings. Visit the Pacemaker website for new ideas in construction and phone 888.834-4448.