If you have a versatile, durable, and economical post-frame or pole-barn building, insulation may be necessary. In our area, we have weather that makes it uncomfortable for people, animals, and equipment as well as unsuitable for running water and many stored products and supplies.

If you have a versatile, durable, and economical post-frame or pole-barn building, insulation may be necessary. In our area, we have weather that makes it uncomfortable for people, animals, and equipment as well as unsuitable for running water and many stored products and supplies.

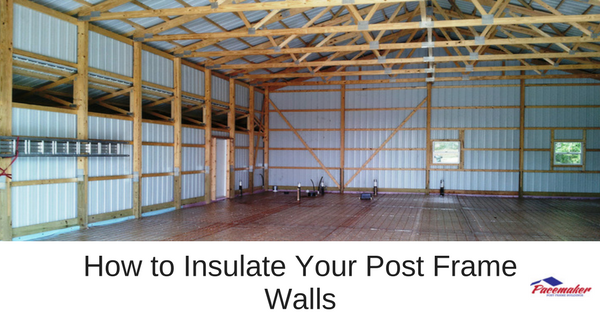

One unique advantage of a post frame building is they are often more energy efficient than standard construction methods. The post frame process places vertical support beams at least six feet apart, allowing the insulation to uniformly cover the interior surface.

With stick framed construction, the vertical supports are spaced 16” apart and cause more “interruptions” in insulation coverage. The wood framing material acts as a conductor of energy, making the standard construction less efficient.

Why Insulate?

Besides keeping the warm or cool inside as needed, insulating your post frame building properly will:

- Save energy costs.

- Keep the inside air dry to reduce the likelihood of mold, rust, and mildew from moisture and condensation.

- Reduce noise levels.

- Create a healthier environment for occupants.

Insulating Design

Ideally, the insulation plan begins with the original building design. Identifying every possible use of the building will help to determine how much and what types of insulation will be used.

The spacing between the vertical columns enhances the insulating properties of either fiberglass or foam insulation. The kind of posts used in the building will determine the thickness of the insulating material.

Depending on the weather conditions, if the facility is to be used primarily by humans the insulating properties should be substantial. If the building is to be utilized for animals or non-liquid or machine storage, the insulation may not need to be as robust.

However, if you are heating and cooling a facility, significant energy savings result from a higher level of insulation.

Applying the Insulation

Not only are post frame buildings often more energy efficient; applying the insulation is often easier than with other types of construction. The vertical columns are connected to each other with 2×6 horizontal nailers creating a wall cavity for securing the insulation.

Moisture Protection

Moisture can be a primary cause of machine degradation, health concerns, and inventory damage. Insulating to prevent condensation in the building can start with Moisturelok condensation control throughout the interior of the metal roof as the first layer of defense.

The product is a membrane made from a felt-like material that holds condensation in the building. When the temperature outside the building drops below the dew point, the moisture is released as normal humidity. The process keeps the moisture level in the structure within a reasonable range.

Proper Ventilation

Designing air intake and output venting will enhance the airflow within the building, particularly if there’s an upper level. Adding sectional vented soffits to the eaves of the building will allow air to flow in while output vents should be integrated on the top ridges of the roof.

Including these air vents in the design will keep your building comfortable in any season and further discourage the build-up of moisture and the accumulation of mold and fumes.

Paneling the Wall Surfaces

An additional enhancement of the overall insulation process is to cover the interior of the insulated walls with steel liner, T-111, etc. Covering the insulation system not only adds protection and is easy to apply to the vertical beams, but it also offers a more “finished” look to the inside of the building.

Have questions? Contact us!